Specification

| Maximum printing size | 1600×3000mm |

| Printing plate thickness | 6.7mm |

| economic speed | 120-130 Sheets/min |

| Main motor power | 30KW |

Description

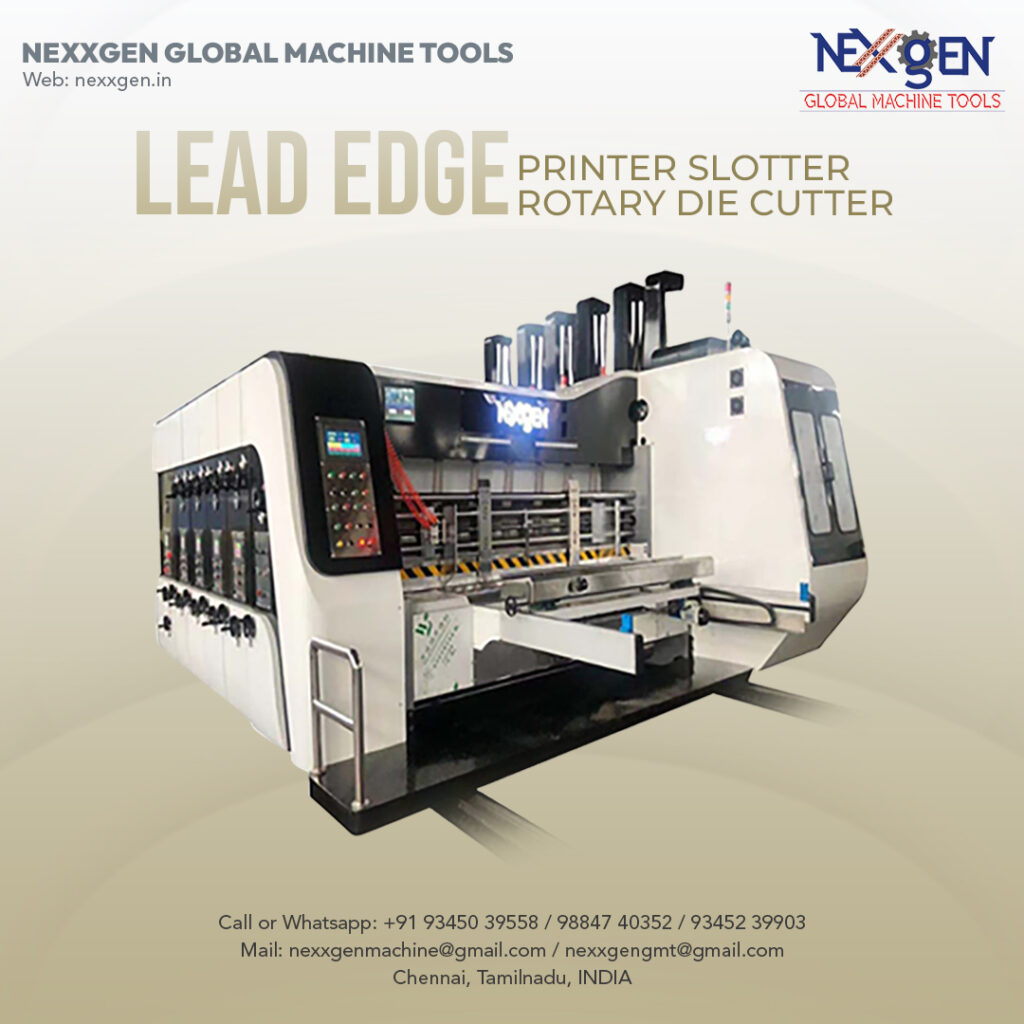

A lead edge printer slotter rotary die cutter machine is an advanced piece of equipment designed for the packaging industry. This machine combines high-quality printing, accurate slotting, and efficient rotary die-cutting into a single, streamlined process. The lead edge feeding system ensures accurate and consistent material handling, while the rotary die cutter provides high-speed and precise cutting of various shapes and designs.

Product Features

1.Lead Edge Feeding System

- Accurate Feeding: Ensures precise alignment of materials for printing and die-cutting.

- Adjustable Feed Settings: Accommodates various material sizes and thicknesses

2. High-Quality Printing

- Multiple Color Options: Typically supports multi-color printing for vibrant and detailed graphics.

- Quick Changeover: Easy and fast change of printing plates and colors for different jobs

3. Slotting Mechanism

- Precision Slotting: Accurate slotting for creating flaps and slots in corrugated sheets.

- Adjustable Slotting Heads: Customizable slot positions to meet different box design requirements

Machine In Action

Key Features and Benefits:

High Precision: The lead edge feeder guarantees precise sheet feeding into the machine, minimizing waste and enhancing production quality.

Versatility: These machines are capable of handling corrugated sheets of varying sizes and thicknesses, making them ideal for a wide range of box designs.

Efficiency: Integrating printing and slotting into a single machine simplifies the production process, reducing both time and labor expenses

Customization: They can be adapted for various print designs and slotting configurations, enabling a broad range of box styles and branding possibilities

Applications

![]()