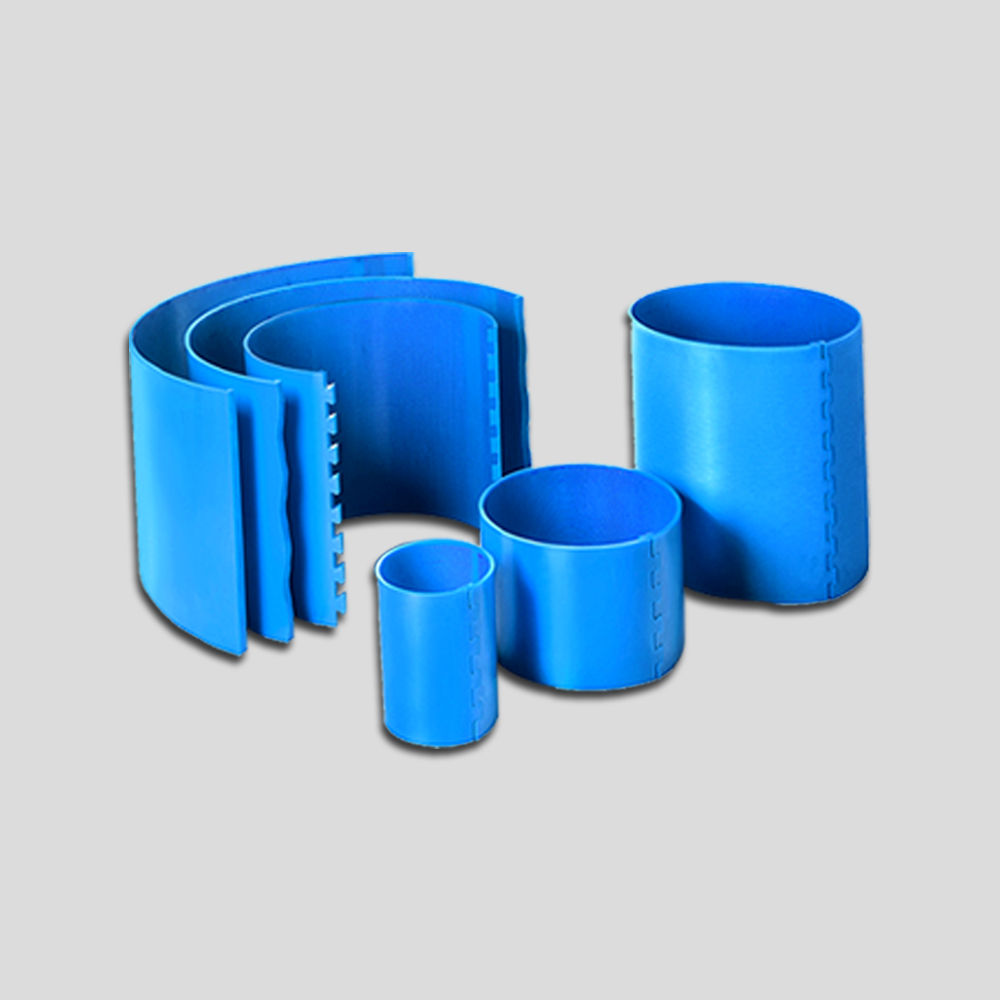

An anvil cover or pad is an essential component used in the corrugated packaging industry, specifically in rotary die-cutting machines. It is mounted on the anvil cylinder and provides a surface against which the cutting dies press to create precise cuts and creases in corrugated board.

Applications:

- Corrugated Packaging:

- Rotary Die-Cutting: Used in rotary die-cutting machines to provide a durable surface for cutting dies to press against, enabling the precise cutting and creasing of corrugated board.

- Scoring and Creasing: Ensures accurate scoring and creasing of corrugated sheets to facilitate folding into boxes.

- Cardboard Manufacturing:

- Box Production: Essential for producing various types of corrugated boxes, including regular slotted containers (RSC), die-cut boxes, and custom-designed boxes.

Features:

- Material Composition:

- Durable Materials: Typically made from high-quality polyurethane or other resilient materials that resist wear and tear.

- Elastic Properties: Provides elasticity to absorb the impact of the cutting dies, extending the life of both the anvil cover and the dies.

- Precision Engineering:

- Uniform Thickness: Ensures consistent thickness across the entire surface for uniform pressure distribution and accurate cuts.

- Surface Texture: Designed with a specific surface texture to prevent slippage and ensure precise cuts.

- Easy Installation and Replacement:

- Mounting System: Features a user-friendly mounting system for easy installation and replacement, reducing machine downtime.

- Compatibility: Available in various sizes and specifications to fit different rotary die-cutting machines.

- Maintenance and Longevity:

- Self-Healing Properties: Some anvil covers have self-healing properties that help close up small cuts and nicks, extending their usable life.

- Wear Resistance: High resistance to abrasion and cutting forces, ensuring long-term durability.

Benefits:

- Improved Production Efficiency:

- Consistent Quality: Ensures consistent cutting and creasing quality, reducing the need for rework and improving overall production efficiency.

- High Throughput: Enables high-speed die-cutting operations, increasing production capacity.

- Cost Savings:

- Extended Die Life: Reduces wear on cutting dies, extending their lifespan and lowering replacement costs.

- Reduced Downtime: Easy installation and long-lasting performance minimize machine downtime, enhancing productivity.

- Enhanced Product Quality:

- Precision Cuts: Provides a precise and uniform cutting surface, ensuring high-quality cuts and creases on corrugated sheets.

- Accurate Folding: Ensures accurate scoring and creasing, leading to better folding and assembly of boxes.

- Versatility:

- Wide Range of Applications: Suitable for various types of corrugated board and box designs, making it a versatile component in the packaging industry.

- Custom Solutions: Available in custom sizes and specifications to meet specific production requirements.

nexxgengmt –

5 STAR