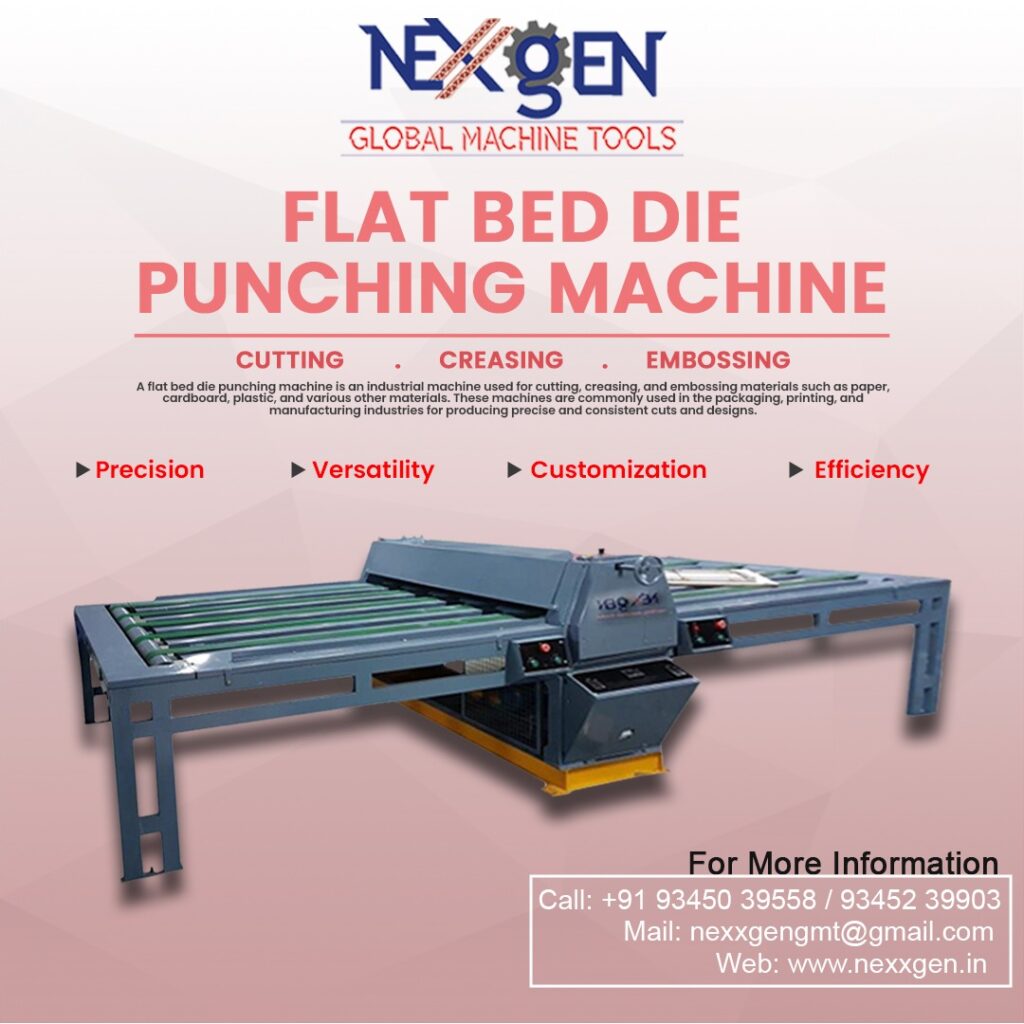

A flat bed die punching machine is a specialized piece of equipment used primarily in manufacturing and packaging industries for cutting, creasing, and perforating various materials such as cardboard, paper, plastic, and thin metals. These machines are designed to perform precise cutting operations using a flat bed die, which is a flat surface where the material to be processed is placed, and a punch that presses down to cut the material according to the die’s design.

Key Components

- Flat Bed: The flat surface where the material is placed for cutting.

- Die: A customized cutting tool made from steel or other durable materials that has the specific shape and pattern to be cut.

- Punching Mechanism: This can be mechanical, hydraulic, or pneumatic, and it provides the force needed to press the die into the material.

- Feed Mechanism: Automatically feeds the material into the machine for continuous processing.

Applications

- Packaging Industry: Creating boxes, cartons, and other packaging materials.

- Printing Industry: Cutting printed materials into specific shapes and sizes.

- Electronics Industry: Cutting insulating materials and other components.

Advantages

- Precision: High accuracy in cutting complex shapes.

- Efficiency: Fast processing speeds for high-volume production.

- Versatility: Can handle various materials and thicknesses.

Specification

| Model | 2200mm |

| Power | 2.2kw |

| Source | 3-415 V |

| Weight | 1.5T |

| Overall Size | 2000 X 3400 X 1350 Mm |

| Max .Size Of Box | 2100 X 1300mm |

| One-Sided Maximum Paste Box Size | 1000 X 1300mm |

| Min Size Of Box | 200 X 260mm |

Description

A semi-automatic folder gluer machine is a type of equipment used in the packaging industry to fold and glue flat paperboard into boxes or cartons. These machines are semi-automatic because they require some manual input or assistance during the operation, but automate much of the folding and gluing process. Here’s a brief overview of its components and functions:

Machine In Action

![]()